Going green has advantages for the North African nation as it looks to tie its established mining and automobile sectors to battery production

Morocco is hoping to move beyond its established mining sector and develop its electric vehicle industry, as it looks to move up the value chain in car production and spur more job creation.

The North African nation has emerged as an automobile manufacturing hub with exports from the industry hitting more than $10bn dollars. In 2018, the kingdom surpassed South Africa as the continent’s top producer of passenger vehicles.

That represents a victory for Rabat, which has prioritised investments in infrastructure and business-friendly reforms in order to boost domestic manufacturing.

And with 220,000 Moroccans employed in the industry, the country is looking to position itself as a hub for the production of electric vehicles.

“The next biggest challenge for the automotive industry in Morocco is this transition to electric cars,” Rachid Aourraz, co-founder of the Moroccan Institute for Policy Analysis, told Middle East Eye.

So far, Morocco appears to be doing alright. In 2020, Citroen, the French brand of automobiles owned by Stellantis, introduced a fully electric mini-car produced in its plant in the coastal city of Kenitra. More companies are following suit.

Chinese electric vehicle maker BYD recently signed a preliminary agreement to open a factory in Mohamed VI Tangier Tech City, and, in August, Stellantis announced that its German car manufacturing subsidiary Opel would start producing electric vehicles (EVs) in Morocco.

‘Buyers want to diversify risk’

Othmane Kotari, a senior adviser on Morocco and North Africa with Albright Stonebridge Group, told MEE that the kingdom was particularly focused on developing its own batteries to complement the production of EVs.

“There are ongoing discussions with European car manufacturers to allocate some resources to developing EV batteries,” he stated.

Battery production has sparked a special interest in Morocco, given the country’s deposits of cobalt, the rare metal critical for the production of EVs’ lithium-ion batteries.

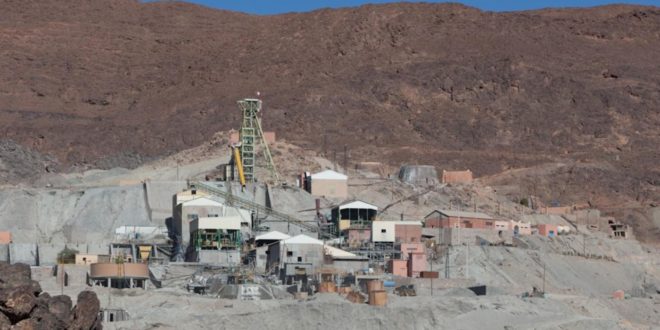

Nearly all of Morocco’s cobalt is sourced in the southern province of Ouarzazate, at the Bou Azzer mine owned by Managem, a private company listed on the Casablanca stock exchange in which the royal family also maintains a stake.

This summer, Energy and Mining Minister Aziz Rebbah said the government would put a special focus on increasing output of “strategic metals”, particularly those used in the renewable energy sector.

The amount of cobalt in Morocco, estimated at 2-3 percent of the world’s reserves, pales in comparison to Africa’s main producer, the Democratic Republic of Congo (DRC), which churns out roughly 70 percent of global supply.

Yet the DRC’s cobalt has been tarnished over reports of child labour and unsafe and inhumane working conditions. Yassine Belkabir, founder and managing director of AB Mining Consultants in Casablanca, says this has allowed Morocco’s mining industry to distinguish itself from its African competitor.

“Moroccan cobalt is produced with higher levels of environmental and social scrutiny,” Belkabir said. “The cobalt production chain is generally transparent, responsible and traceable from mine to final product.”

Mohamed Amine Afsahi, executive director of sales and marketing at Managem, told MEE that this allowed the company to demand a premium for its cobalt.

“Buyers want to diversify their risks,” he said, pointing to political instability in the DRC while adding that Managem had taken steps to show its Cobalt was mined with respect to sustainability standards.

Last year, the company signed an agreement with BMW to supply the German car manufacturer with around one-fifth of its cobalt needs for the fifth generation of its electric drive trains. The deal, which will span a five-year period, was trumpeted by the automaker as a testament to its commitment to ethically sourcing the metal.

Afsahi said the agreement was, “only the first piece of the puzzle”, and that further deals with other car manufacturers were in the works:

“Demand for cobalt for the next ten years is huge. The market already has a deficit.”

‘Build an ecosystem around the EV battery’

But Kotari says Morocco’s goal was strategic, to move beyond merely supplying the raw material to processing it inside the country and using it in domestically made batteries. “They want to link the cobalt to EV manufacturing,” he said.

He added that government support for the plan and the presence of an already sizable car manufacturing hub in the country had generated investor interest.

“The idea is to build an ecosystem around the EV battery, going from the commodity up to the recycling of old batteries,” he said. “All the component parts are already here.”

Unlike in other countries, where the metal is extracted along with copper and nickel, Moroccan cobalt is mined as a standalone product and is known to be one of the purest varieties in the world.

Managem exports nearly 100 percent of the cobalt from its Moroccan mine. Belkabir says making the jump from exporter to user of the metal will require “incremental investments” within the industry.

The bulk of cobalt produced by Morocco in its current form – as cut cathode – is not directly suitable for the lithium-ion batteries in EVs. The metal needs to undergo chemical conversion via a tolling process into a sulphate form.

Afsahi says Managem is committed to making this investment, and is in talks with EV and battery makers about future partnerships: “The cobalt we are mining will be processed here in Morocco to produce materials for the batteries.”

While the government has been highly supportive of efforts to expand the EV industry, challenges remain. “The state wants to further specialise the automative industry, but this can’t be achieved without R&D, and the state doesn’t have the funding at the moment,” said Aourraz.

‘The need for cobalt will never go away’

Michael Tanchum, a non-resident fellow in the Economics and Energy programme at the Middle East Institute, told MEE that the kingdom had a successful track record of attracting foreign investment, adding that this development would fit with the government’s goal of boosting domestic production in the automobile industry.

“Local component manufacturing in Morocco has made the kingdom into Africa’s automotive manufacturing powerhouse,” he said. “EV battery production within Morocco would spur the expansion of its EV manufacturing sector.”

While demand for cobalt is expected to stay high for some time, one of the challenges for the mining industry is that battery producers are already looking for alternatives to the costly metal.

The bulk of cobalt produced by Morocco in its current form – as cut cathode – is not directly suitable for the lithium-ion batteries in EVs. The metal needs to undergo chemical conversion via a tolling process into a sulphate form.

Afsahi says Managem is committed to making this investment, and is in talks with EV and battery makers about future partnerships: “The cobalt we are mining will be processed here in Morocco to produce materials for the batteries.”

While the government has been highly supportive of efforts to expand the EV industry, challenges remain. “The state wants to further specialise the automative industry, but this can’t be achieved without R&D, and the state doesn’t have the funding at the moment,” said Aourraz.

‘The need for cobalt will never go away’

Michael Tanchum, a non-resident fellow in the Economics and Energy programme at the Middle East Institute, told MEE that the kingdom had a successful track record of attracting foreign investment, adding that this development would fit with the government’s goal of boosting domestic production in the automobile industry.

“Local component manufacturing in Morocco has made the kingdom into Africa’s automotive manufacturing powerhouse,” he said. “EV battery production within Morocco would spur the expansion of its EV manufacturing sector.”

While demand for cobalt is expected to stay high for some time, one of the challenges for the mining industry is that battery producers are already looking for alternatives to the costly metal.

“It’s the future, and it’s a very attractive business that has a high return and less risks than mining,” he said. “You produce the cobalt, you deliver it to the manufacturers, then recycle it.”

Importantly for investors, the government in Rabat appears eager to develop the industry. “They want to ease the investments around this sector,” Kotari said.

Tangible signs of the kingdom’s commitment can already be seen. Besides producing entry-level EVs such as Citroen’s AMI in Kenitra, this year Morocco became the first country in Africa to get Tesla car charging stations.

It is developments such as these, along with support from the country’s powerful royal palace, that have created a palpable buzz around the industry.

“Moroccan EV battery production may soon be on the horizon,” Tanchum said.

_____________________________________________________

(*) This article was originally published on Middle East Eye. Read the original article. The views expressed in this article belong to the author and do not necessarily represent ForMENA

ForMENA Council for MENA affairs

ForMENA Council for MENA affairs